System Simulation

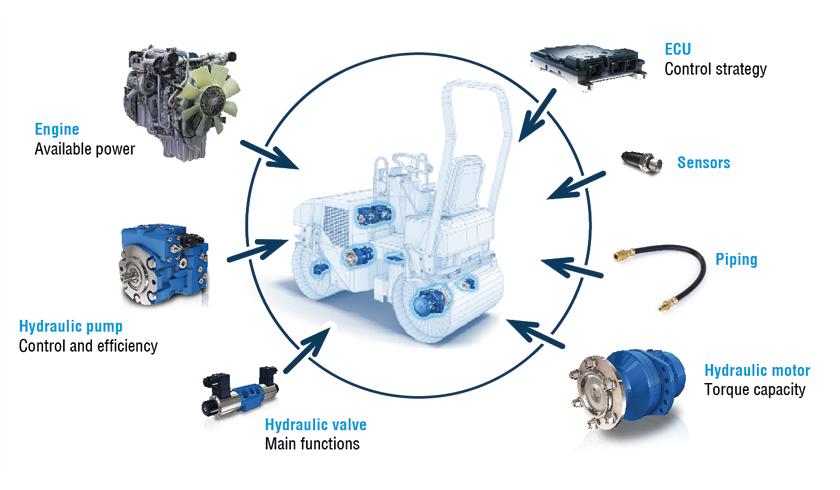

FROM COMPONENT TO MACHINE

In an increasingly competitive and regulated environment, deeper machine optimization studies can be a decisive step in becoming more competitive and better meeting market requirements.

Poclain theoretical sizing tools are well suited in many cases, but there is a growing interest in more in-depth studies. This is the case when downsizing diesel engines, which is often necessary to satisfy stricter pollution standards, or machine electrification .

System Simulation helps address optimization needs and anticipates risks in advanced prototyping phases.

Simulation is a powerful tool for optimizing machine performance, as it takes into account the specific system characteristics such as efficiencies, control strategies and hoses, as well as external elements such as the internal combustion engine, auxiliary consumption, tire data, and ground adherence.

The machine behavior is analyzed according to specific scenarios or maneuvers, and results can be weighted over realistic operating cycles. We are then able to evaluate how each component of the system contributes to overall energy consumption, responsiveness, performance and driving comfort as well as their impact on the thermal behavior of the transmission.

By confirming the performance resulting from the design choices, we can focus development efforts on the most relevant elements.

Simulation and virtual commissioning make it possible to anticipate customer expectations, consolidate technical specifications and guide developments as early as possible in order to improve development processes for OEMs.

Assessing the system performance

Main steps of the System Simulation process

- Identify deliverables and means to be implemented

- Collect required data, detailed calculations and construct associated system models

- Carry out the first simulations

- Identify points of vigilance and areas for improvement. Optimization proposals and confirmation that we are in line with the initial request

- Assessment of alternative solutions and recommendations based on the obtained results

- Issue a report summarizing the initial requirements, the procedure, the assumptions made and the results of the simulations