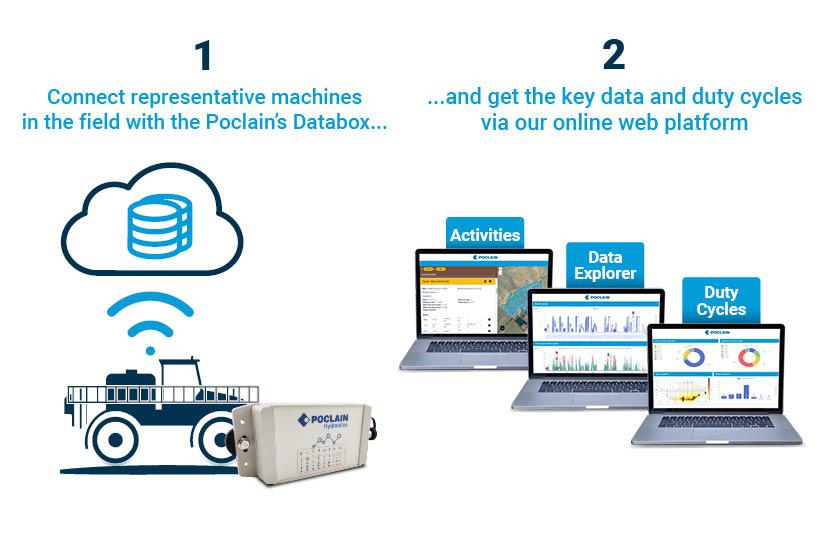

Direct Online Duty Cycle Analysis

Access the essential data needed for your design-to-usage machine developments.

CONNECT AND LEARN!

Deepen your knowledge of your machines and their applications

- Solution easy to deploy

- Automatic data processing

- Factual data from the field

- Data directly accessible to your project technical teams 24/7

Need a deeper analysis of your machine's operations?

With expert report service, Poclain data and applications experts can conduct in depth analysis to focus and answer your specific questions.

For more information, please contact:

- Your local sales man

- services.contact@poclain.com