3D Integration

TO EASE AND GUARANTEE YOUR PROTOTYPING SUCCESS

Whether for an industrial or a mobile application, most new projects call for prototyping. Carried out on-site by a field technician, it often requires craftmanship and time to integrate the components into their environment.

With the 3D integration service, Poclain Hydraulics brings customers support and expertise to ease and guarantee a prototype according to your expectations, while reducing development time.

Integration study based on the 3D digital machine environment

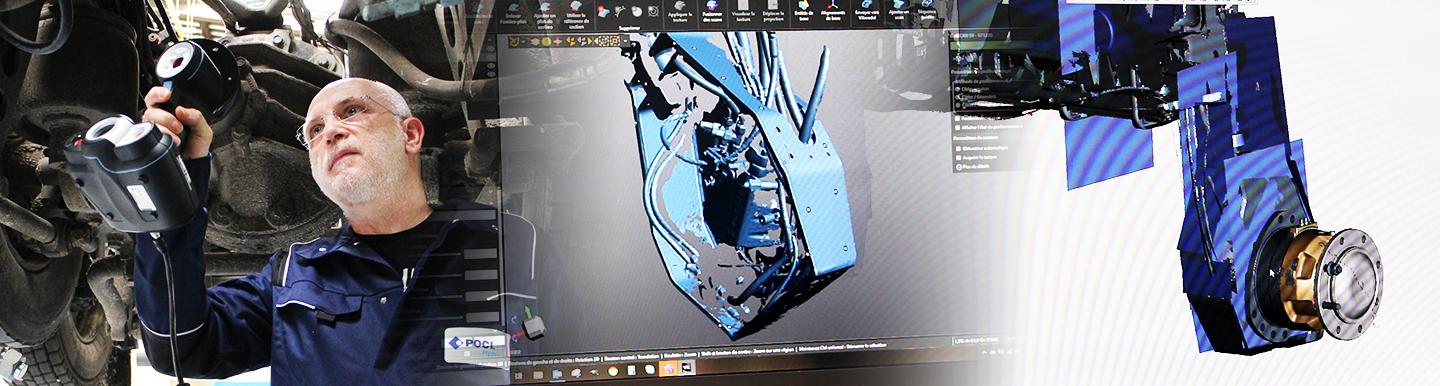

Poclain Hydraulics steps up your prototyping with a handheld 3D scanner, to generate the components and system integration environment 3D files :

- Digitalization process managed by a Poclain Hydraulics technician specifically trained in scanning complex environments and 3D files post-processing software

- Quick, precise, flexible, and no-contact process

- Scanning can take place anywhere the machine is located, the machine does not need to travel

- Possibility to take into account different environments, configurations or machine range variants

- Functional elements’ identification for accurate measurements, geometric evaluations, and system integration studies

The flexible digitalization process helps you to anticipate difficulties and geometry defaults before prototyping on the machine. You can save time by reducing the delay of producing a reliable prototype, and stay focused on your core business.

THREE LEVELS OF SERVICE

- 3D scan of the machine environment

- Scan of the machine to generate the 3D digital environment

- Creation of reference surfaces to identify the functional elements

- 3D files delivered ready to be used for component or system integration study

- Components Integration status

- Component integration study in the digital environment, taking machine real architecture into account

- Anticipate difficulties before prototyping

- Report with recommendations delivered to support prototyping and resolve integration interferences

- Full system integration proposal

- Full component and system integration study in the digital environment

- Poclain Hydraulics expertise, from clarifying integration interferences up to full system integration

- Report with technical recommendations delivered for prototype production support