Mini Loader

An All In One Transmission System

Poclain Hydraulics provides a complete solution, highly recognized in the market, offering outstanding traction control and reliability for Mini-Loaders.

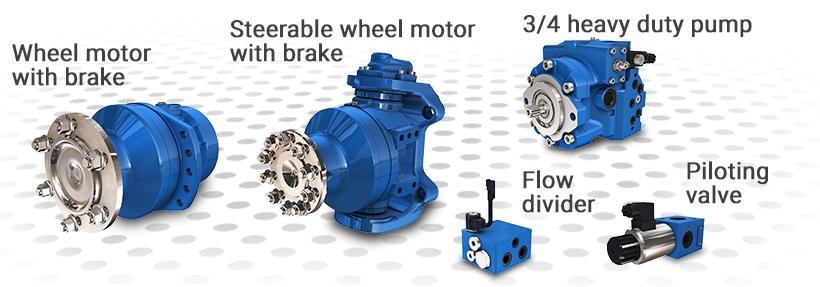

Poclain Hydraulics’ core offer for your mini-loaders

Our core hydrostatic solution is maintenance-free and delivers multiple advantages compared to axle machines for your multi-functional mini-loaders.

OUR STANDARD SOLUTION

- Serial circuit

- Four wheel motors

- One variable displacement closed loop ¾ heavy duty pump with automotive, hydraulic or electronic control

- Mechanical and hydraulic inching

- One piloting valve KVC for brake and gear speed

- One serial protection block for anti cavitation and safety

AVAILABLE OPTIONS

- Integrated steering pivot motor

- Hydraulic automotive control

- Electronic automotive control with embedded software for higher accuracy

- Speed sensors

- Flushing valve

- Integrated multi-disc parking brake

- Parking brake valve

WHAT DO YOU GAIN?

- High maneuverability with simple and reliable wheel drive solution versatility

- Reduction of ground damage thanks to anti-skid system

- Reduced fuel consumption

- Less parts management and maintenance cost compared to axle solution

- Increased operator safety due to a lower center of gravity (vs axles machines)

- Increased machine payload compared to similar weight class (vs axles machines)

- Wider flexibility in the machine design features (narrow dimensions)

Flexible Design

Easy Integration with Free Space Between Wheels

Productivity

Optimized Traction Control in Any Condition

Reliability

Poclain Hydraulics as Market Reference & Leader in Hydrostatic Transmission for Mini-Loaders

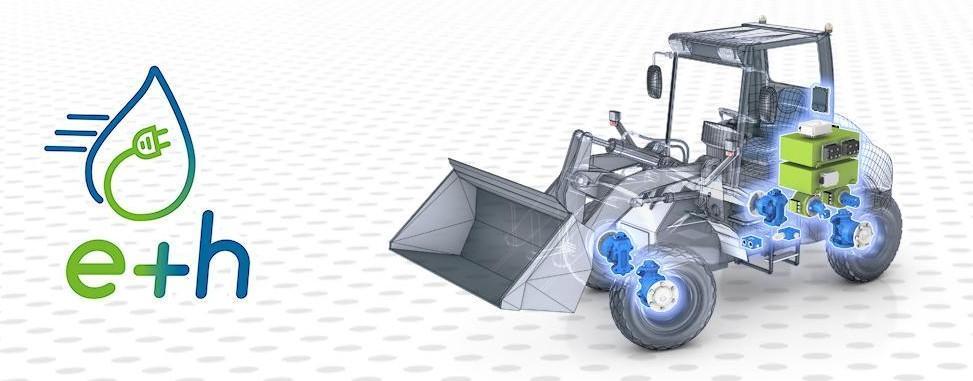

Electrification Solution For Your Mini-loaders

e+h is the Poclain Hydraulics electrification solution that will support you creating differentiating zero emission machines with performance similar to Diesel versions and optimized battery life. e+h accelerates your time to market with a solution maintaining current rugged hydrostatic core and reduces your development costs and industrial investments thanks to high commonality with Diesel platforms.