e+h Electrification Solution

e+h solution

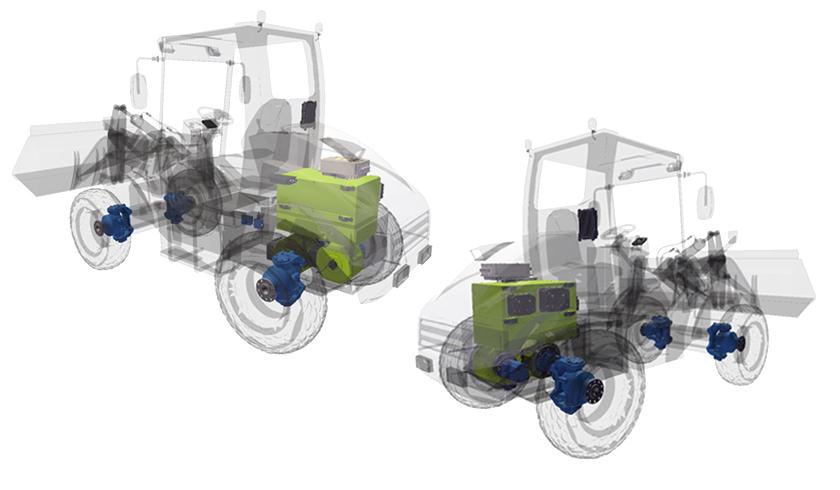

Zero emission equipment’s are part of the worldwide landscape in agriculture, material handling, construction and other markets. The trend will accelerate within current decade and Poclain Hydraulics is taking part to this evolution with the aim to create differentiating electric solutions. e+h is the flexible and efficient electrification solution built for OEMs to develop their electric off-highway machines. It is combining advanced engineering services with a versatile system platform.

e+h perfectly fits with compact machines like wheel loaders, multi-tool carriers, site dumpers, truck-mounted forklifts, tandem rollers, mini compact track loaders, autonomous agricultural machines and many other ones with similar characteristics. e+h is particularly well suited for the electrification of current Diesel machine platforms.

e+h system

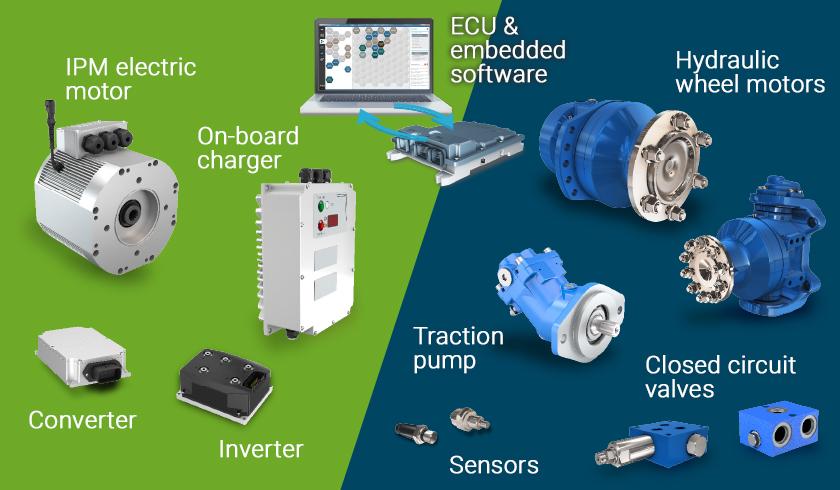

The hybrid e+h system is comprised of rugged hydraulic components based on cam-lobe in-wheel technology and state-of-the-art electric, power electronics and electronic components combined with an advanced embedded control software.

The machine integration, highly critical on small equipment’s, is strongly optimized thanks to the in-wheel ultra-compact configuration. Moreover, e+h transmissions operate 4-quadrants so the regenerative braking increases the vehicle range and reduces the battery size.

e+h engineering services

e+h is also a complete engineering services package built for OEMs to externalize very efficiently the engineering work required to develop their electric transmission and power supply to auxiliaries. The value-added e+h engineering services are deployed throughout customer projects, from the expression of the needs up to the serial life in OEMs’ factories, including the prototype development.

The services package is comprised of: connected engineering for duty-cycle consolidation on Diesel machine, components sizing and selection, system simulation, embedded software specification and development, support to system functional safety assessment, support to system integration, electric prototype commissioning including connected commissioning, customer trainings.

Benefits for OEMs

e+h has been designed and built as OEM-centric. With e+h, you get decisive benefits:

- Your Marketing and Sales teams can offer electric machines with an accelerated time to market. The electric machines are at least as performant as Diesel ones and profit from a high ruggedness thanks to their time-proven Poclain Hydraulics hydrostatic core

- Your R&D teams have reduced development costs as well as more peace of mind thanks to the complete high added-value engineering services package

- Your Industrialization teams have the chance to lower their investments because the current assembly lines are slightly impacted

- Your Supply Chain and Aftersales teams benefit from simplified procurement flows and stocks thanks to the high commonality with Diesel platforms

Benefits for end users

In addition, e+h creates benefits for machine users and owners:

- The electrified machines are zero emission (particulates and gas) and have a reduced emitted noise level, which enables them to access to restricted areas (low emission zones, zero emission zones, underground zones, public and private zero emission sites…)

- Compared to the Diesel machines, the ones electrified with e+h have reduced total cost of ownership (TCO) coming from lower maintenance and fuel costs

- Equipped with the e+h solution, the machines are ready to embed additional advanced functions and connected services and promote ecological image and usage

Typically targeted machines

- Mini wheel loader

- Multi-tool carrier

- Mini site dumper

- Truck-mounted forklift

- Mini compact track loader

- Light tandem roller

- Autonomous agricultural machines

A mini loader manufacturer uses the e+h solution: feedback from Norcar

The Finnish manufacturer Norcar has chosen Poclain Hydraulics for the electrification of one mini loader.

For any electrification project or information request, please get in touch with your current Poclain Hydraulics contact.