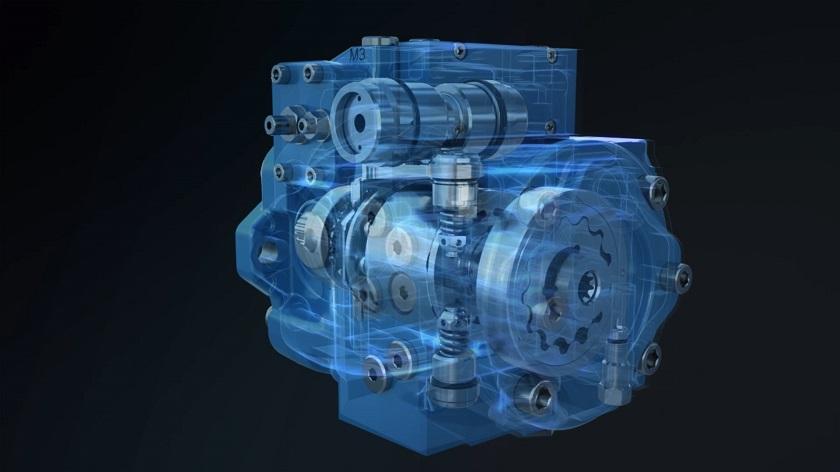

PM20 PUMP THE BIG SISTER OF OUR PM10

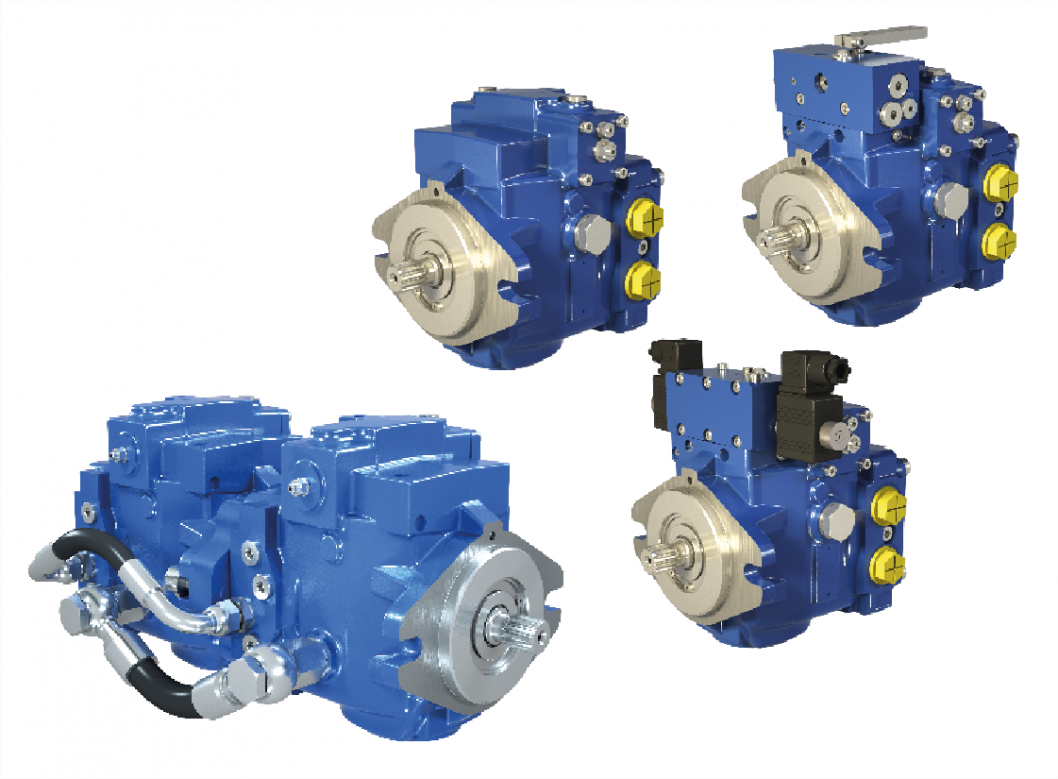

Only slightly larger than our PM10, it is up to 30% faster and is a good answer for the propel drive of compact machines in the range of operating weights from 1,5 to 2,5 tons. The highly customizable pump is only 198 mm with the charge pump, while many of our competitors offer pumps that are 215 mm. This makes it easy and quick to install with a minimal disruption to normal operations. The PM20 is ideal for the construction and agricultural industries and is also aimed at the road building machinery segment

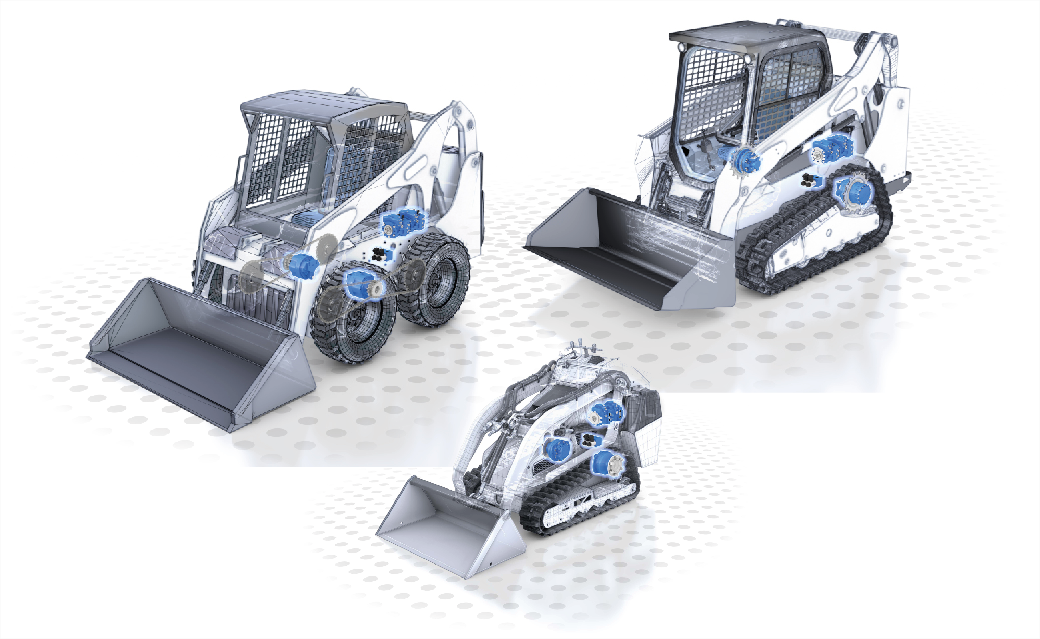

Real World Success On Skid Loaders

Dynamic. Extreme. Tireless. Skid loaders work from dawn to dusk to collect, load and transport all types of material in a limited space with uneven and treacherous terrain. Poclain Hydraulics has been dedicated to helping skid loader manufacturers perfect their machines throughout the prototyping phases to produce the best axial piston pumps for their needs.

Vision For The Future Of The PM20

Poclain Hydraulics plans to continue to lead in the hydrostatic system supply sector through the utilization of our plant in Gaggio, Italy. It is a hub in the design and production of hydraulic pumps and built the PM20 to be the best performing medium duty pump in its range.

We are continuing to invest in this initiative by adding new production machines, such as a double table vertical machining center, to meet increasing customer demands leading to more effective production. The center offers exceptional cutting combined with a double pallet configuration that increases productivity. The entire system is designed for increased speed and accuracy, features powerful drives, heavy cutting capacity and unsurpassed stiffness to deliver exceptional cylinder barrel manufacturing.

As always, the goal of the Poclain Hydraulics team is to offer to our customers the best quality and performance in all of our products. The future includes essential investments in our production processes, innovation and improvement of processes and enhanced communications with our customers to understand what they want and deliver it to or exceeding expectations.

Our new PM20 fills the gap between our well established PM10 and our recently introduced PM30 pumps and will contribute to enhancing our customers’ machines performance.

Filippo BUZZONI

Axial portfolio Manager

Poclain Hydraulics