Combo Valves Save Time, Money And Space

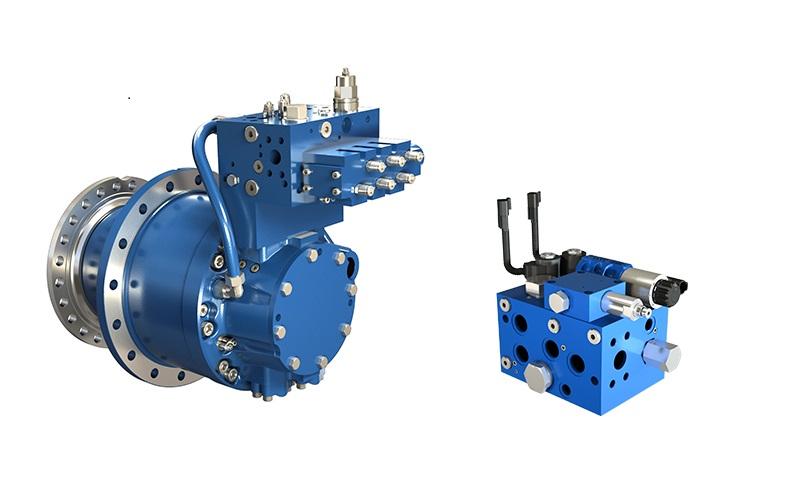

Poclain combo valves also combine all needed functions of the hydrostatic drive. They are designed as a standalone mount or to be seamlessly integrated on motors or pumps.

Possible combo valve functions

- Free-wheeling to engage or disengage a hydraulic motor or motors (VDF valves) – Assist DriveTM.

- Traction control with flow divider, medium to heavy duty range (FD-M and FD-H valves).

- Electronically managed traction control valve (VMA valves).

- Exchange function to bleed hot oil from the low pressure side of a hydrostatic transmission circuit to be cooled, filtered or used as a source of oil for flushing pump and motor cases (VE valves).

- Pilot functions: Speed shifting valve and park brake control (KV, KVC valves).

- Directional control valves: For instance, diverter valves or valves to change the turning direction of some wheels (KV and KVHP valves) for side-way drive or zero-turning radius.

- Protection functions: high-pressure relief valves, serial protection valves, etc.

- Other functions as needed.

How long does it take to design and deliver a combo valve?

It all depends on the application, but it is not a long process (compared to new basic function development) as we combine existing functions to meet customer demand. Many combo valves already exist and can be quite easily customized to another application – typically it is free-wheeling function plus traction control with flow divider and an additional exchange function.

Applications for combo valves

Our valves have been successfully used in several markets such as agriculture, construction and material handling machines; including harvesters, motor graders, fork-lifts and other machines; as well as various applications in the industrial market.

Benefits of combo valves

- Less hydraulic losses due to less fittings and piping.

- Less needed space on the machine – one combo valve instead of several valves connected together with hydraulic hoses.

- They come with decreased costs associated with the elimination of certain piping, hoses and other associated components (fixation elements).

- Lower risk of leakages – no piping between several components.

- They are easy and quick to install - saving time and man hours.

- They increase safety with fewer hoses under high pressure.

- Finally Poclain combo valves make “clean machines” with less space needed for the installation and less connections.

Ales NOVAK

Product Portfolio Manager

Poclain Hydraulics