[Case Studies] 20 Years Of Partnership With Log Max Harvesting Heads

The collaboration between Log Max and Poclain is driven by shared values and a focus on delivering high-quality, customized products in their respective niche markets. Log Max has inspired Poclain to push further the ruggedness and efficiency of their camlobe design, leading to improvements that are applied to other applications.

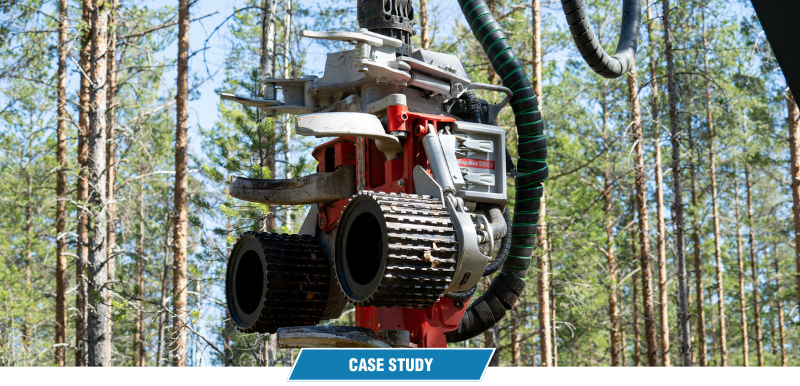

Log Max’s most recent development, the upgraded 5000V harvesting head, integrates two MSE05 motors with the Optiflow option.

With an annual turnover of 500 million Swedish Krone (close to $49 MN USD), Log Max, a mid-sized Komatsu owned Swedish company, challenges large multinationals with the broadest harvesting head portfolio on the market, ranging from 420 to 4,270 kgs load capacity.

"Our design philosophy revolves around simplicity and consistency, with a common architecture throughout our range, and we are sticklers for quality", says Johan Ericson, R&D Manager at Log Max.

The manufacturer is known for its robust frames that couple to all the carriers on the market, as well as the high uptime of their heads.

Poclain’s technology enhances the performance of Log Max harvesting heads

Poclain, on the other hand, is renowned for its high torque technology, which plays a vital role in the exceptional performance of Log Max’s harvesting heads. Poclain’s motors have a high power-to-weight ratio, contributing to a reduction in head weight. The motors also boast high volumetric efficiency, allowing precise cutting to the required length, while their low pressure drop enhances cutting speed and fuel efficiency.

The high-performance Log Max 5000V integrates Optiflow feature

In the redesign of Log Max’s 5000V harvesting head, Poclain further improved the distribution of their MSE05 motors to minimize pressure drop. The feature, branded Optiflow, provides either faster harvesting or fuel saving capabilities, depending on how the operator uses the head.

Optiflow for higher speed and efficiency

Optiflow is Poclain’s new distribution design that targets the forestry industry, as well as applications with higher speed requirements, such as feeder mixers, conveyors, sweepers, crushers, and trenchers.

With Optiflow, pressure losses are cut by over 50%. The max speed of the Optiflow MS05 is 520 rpm, versus 350 rpm for the standard version.

Optiflow is lighter and more compact than a standard MS and is available on single-speed MS motors, sizes 02 and 05 without brake.

Erik Wiik, Swedish tree harvesting influencer, reviews the Log Max 5000V

With close to 700 followers on Instagram and a few hundred on YouTube, Erik Wiik is a notable figure in the Scandinavian tree harvesting world. He puts his outstanding skills to work in the company he runs with his father, harvesting trees for Swedish forest management companies.

Erik and his father use Log Max harvesting heads exclusively, and they acquired the new 5000V head in May. Erik is very impressed with its enhanced features. More rugged, it also has an exceptional starting torque which enables to work up the trunk faster. What’s more, it cuts to length with outstanding precision, which translates into higher revenue as wood contractors reward suppliers who consistently deliver logs of the desired length. “With the new 5000V we have seen a 15% increase in productivity on large tree harvesting compared to its predecessor” says Erik. Poclain’s technology is key in providing the harvesting head’s enhanced performance.